Although thin-film solar panels work like monocrystalline and polycrystalline panels, they differ in their cell technology, efficiency, and durability.

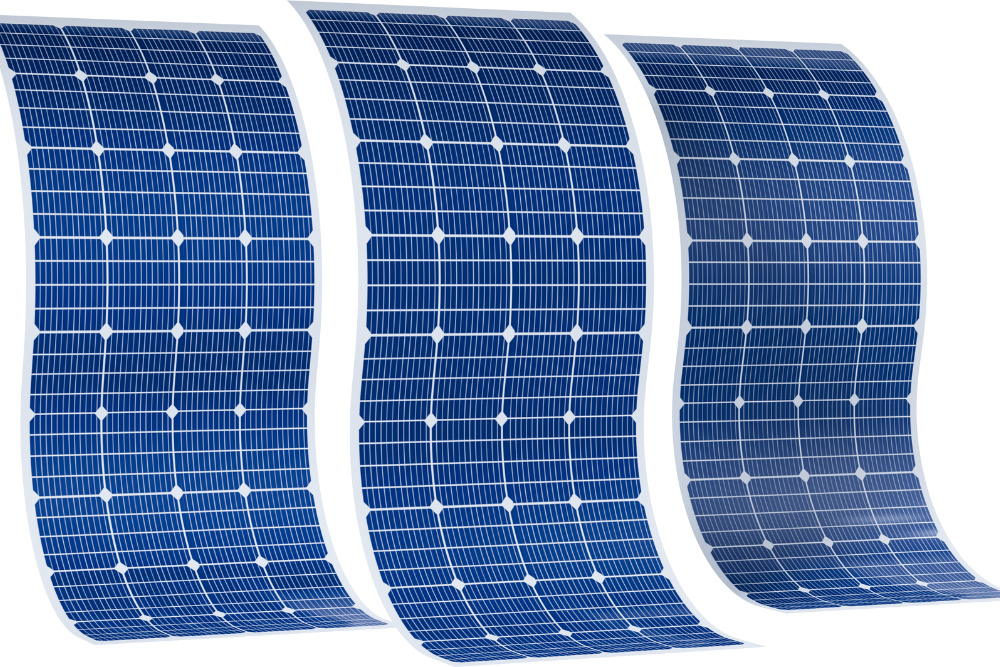

Thin-film solar cells, also known as flexible or stick-on solar panels, are thin and lightweight, unlike traditional solar panels. Their production involves depositing thin films of photovoltaic material on a substrate to produce ultra-thin solar cells.

They are hundreds of times thinner and lighter than the typical crystalline silicon wafers. They’re highly flexible and thus suitable for use in building-integrated photovoltaics and portable devices such as calculators.

How Do Thin-Film Solar Panels Work?

Thin film solar panels work like standard silicon cells by converting solar power into renewable energy. Their cells comprise photovoltaic materials that allow electrons to move, generating electricity.

Types Of Thin-Film Technology

There’s a range of thin film solar panel types based on the materials used in the manufacturing process. As such, they differ in efficiency since some materials have a higher conversion efficiency than others. The most common types include:

Amorphous Silicon (a-Si)

These thin film panels are the most developed type of thin-film technology in the solar industry. As their name suggests, they're made from amorphous silicon, a highly flexible material. However, unlike mono and polycrystalline silicon, amorphous silicon is non-crystalline (it lacks a crystal lattice structure).

The manufacturing process involves depositing the non-crystalline silicon on a glass, metal, or plastic substrate. Unlike other types of thin-film, a-Si solar PV cells do not include toxic materials. In addition, they use a smaller amount of silicon than the traditional solar panel types.

However, these solar modules have the lowest efficiency among the thin-film solar panels at just 6-8%.

Cadmium Telluride (CdTe)

These types of solar panels are made of Cadmium Telluride and are the most common thin-film cells on the market.

They comprise several layers of Cadmium Telluride, a chemical that efficiently captures and converts solar energy into electricity. Hence, they have a higher efficiency rating than the a-Si type, ranging from 10-11%.

However, these solar panels have caused environmental concerns since Cadmium is highly toxic.

Copper Indium Gallium Selenide (CIGS)

Among the most expensive thin-film panels is the CIGS thin-film panels. They're made from Copper Indium Gallium and Selenide layers, and the substrate can be plastic or steel, depending on the intended use.

Like other thin-film panels, CIGS panels have a lower efficiency rating of between 10-12%. In lab settings, CIGS have a high efficiency of up up to 20%.

They also use toxic Cadmium, although in lower amounts than Cadmium Telluride panels.

Organic Photovoltaic (OPV)

OPV thin-film panels are made from organic semiconductor material, usually carbon-based. Though not as common as other thin-film technologies, they're gaining attention due to their sustainability.

Since they use carbon-based materials, their building blocks are readily available. However, their efficiency rating is lower, between 8-12%. Their lifespan is also much shorter because organic materials degrade faster than the chemicals used in other solar technology.

Benefits Of Thin-Film Panels

Thin film panels have many advantages, including:

Lightweight and flexible

Thin-film modules are made of thin layers, making them thin, lightweight, and highly flexible. They're ideal for any roof. Unlike crystalline panels requiring strong rooftops and mounting systems, thin films can be rolled out on the rooftop without support. This also makes them ideal for mobile applications on RVs, boats, or freight trucks.

Low-light performance

The materials that make up thin film photovoltaic cells can absorb light from different wavelengths. Therefore, they function and still produce energy during foggy or cloudy days.

Building integration

Due to their lightweight and flexible nature, thin film solar can be integrated into architectural designs. Thin film solar panels allow architects to transform passive building elements into active energy generators without compromising the aesthetics of a building.

Low-cost

Thin film solar panels are cheaper than crystalline silicon panels because they use smaller amounts of raw materials.

Eco-friendly

Some thin-film types, such as OPV, use biodegradable carbon-based materials so they have a smaller carbon footprint and are better for the environment.

Are There Any Disadvantages Of Thin-Film Panels?

Despite their advantages, thin film technology has a few disadvantages. These include:

- Lower efficiency: Thin film panels have the lowest efficiency in terms of energy and installation space. Therefore, you'll need to install many PV modules requiring a large installation space.

- Shorter lifespan: Thin film technology uses degradable materials that have a shorter lifespan than silicon solar cells, so you may not enjoy a return on investment for long.

- Not as common as silicon panels: Thin-film PV panels are not as common as traditional silicon solar panels, which have the largest market share. Due to their low efficiency, consumers shy away from them. Therefore, they are difficult to find in most markets since manufacturers focus on producing fast-moving panels.

- Some use toxic materials: Some thin films, such as CIGS and CdTe panels, use Cadmium, a highly toxic material. Although it does not harm you or the environment when used, it becomes a problem when disposing of old panels.